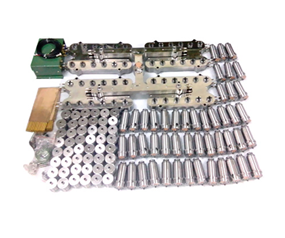

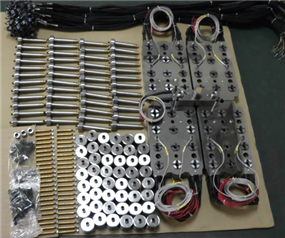

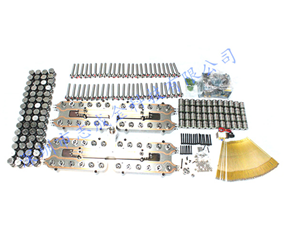

1 out 48-needle valve system

48-cavity needle valve stripper plate hot runner system

### Unparalleled Synchronization (Core Advantage)

- **Simultaneous Action of All Valve Pins**: This is the most core advantage of the stripper plate structure. A precise stripper plate (ejector plate) drives the valve pins of all cavities simultaneously, ensuring that all gates open and close at exactly the same moment.

- **Elimination of Filling Differences**: Synchronous opening and closing eliminate the minor differences in the filling start and end points of each cavity caused by the time differences in the action of valve pins. This is crucial for filling balance, especially when there are minor differences in the cavities themselves or when it is difficult to achieve perfect balance in the runner design.

- **Enhanced Product Consistency**: Synchronous filling significantly improves the consistency of multi - cavity products in terms of dimensions, weight, appearance (such as weld line position, flow marks, gloss) and mechanical properties, reducing the rejection rate and post - sorting costs.

### Precise Filling Control

- **Accurate Control of Filling Time Window**: Synchronization ensures that each cavity starts and ends filling at the set precise time points. This is crucial for controlling the shear rate, avoiding material degradation, controlling the position and strength of weld lines, and preventing flash or short shots.

- **Optimized Packing Stage**: Synchronous closing ensures that all cavities enter the packing stage simultaneously, and the packing pressure can be transmitted more evenly to all products, reducing dimensional differences and internal stresses caused by uneven packing.

### Simplified Structure and High Reliability

- **Few Driving Units**: The entire system usually only requires one or a few (for large - scale systems, it may be divided into zones) powerful driving sources (cylinders or hydraulic cylinders) to push the stripper plate, instead of equipping each valve pin with a separate driving device (cylinder/hydraulic cylinder).

- **Reduced Failure Points**: Fewer driving components mean fewer potential failure points (such as solenoid valve failures, cylinder seal failures, air/tube leaks), improving the overall reliability and stability of the system.

- **Simplified Maintenance**: Maintenance points are more concentrated, making it easier to inspect and maintain the driving system.

### Cost - effectiveness (Especially for High - cavity Molds)

- **Reduced Driving Costs**: For molds with a very large number of cavities (such as 64 - cavity, 128 - cavity or more), the cost of individually configuring driving devices (cylinder/hydraulic cylinder + solenoid valve + pipeline) for each valve pin will be very high. The stripper plate structure significantly reduces the number of driving units, significantly reducing the initial hardware costs.

- **Reduced Control Costs**: The control system is also simplified, and the number of control channels (I/O points) required is greatly reduced.

- **Reduced Maintenance Costs**: Fewer components also mean lower long - term maintenance and spare parts costs.

### Improved Production Stability

- **Reduced Variables**: Uncertain factors such as response time differences and pressure fluctuations that may exist among multiple independent driving units are eliminated, making the production process more stable and controllable.

- **Strong Adaptability**: It has relatively low requirements for the supply stability of compressed air or hydraulic oil, because the fluctuations of a single powerful driving source have much less impact on synchronization than the respective fluctuations of multiple small driving sources.

### Suitable for Specific High - demand Products

- **Precision Parts**: Products with extremely high requirements for dimensional tolerances (such as electronic connectors, optical components, medical parts).

- **Thin - walled Products**: Products that require extremely fast and precise filling to avoid premature cooling.

- **Products with High Appearance Requirements**: Products that require strict control of weld line positions, avoidance of flow marks or ensuring surface gloss consistency (such as mirror - finished casings, decorative parts).

- **Shear - sensitive Materials**: Materials that require precise control of filling time and shear rate to prevent material degradation.

- **Multi - cavity Products with High Consistency Requirements**: Any application that requires products produced from multiple cavities to be almost identical.

### Aspects Requiring Attention

- **High Requirements for Machining and Assembly Precision**: The machining and assembly precision of the stripper plate itself and the related guiding mechanisms is extremely high to ensure that all valve pins are evenly stressed and move smoothly without jamming. Otherwise, the advantage of synchronization will be lost and even problems may occur.

- **Mold Space Requirements**: The stripper plate mechanism requires additional mold space (height), which may increase the overall thickness of the mold.

- **Flexibility Limitations**: All valve pins must act simultaneously, and independent timing control of individual cavities (such as sequential valve control) cannot be achieved. It is not applicable in special scenarios where the filling time needs to be deliberately staggered to optimize the filling of specific cavities.

- **Potential Wear Points**: The contact points between the stripper plate and the driving rods and guides are potential wear points, which require good lubrication and maintenance.### Unparalleled Synchronization (Core Advantage)

- **Simultaneous Action of All Valve Pins**: This is the most core advantage of the stripper plate structure. A precise stripper plate (ejector plate) drives the valve pins of all cavities simultaneously, ensuring that all gates open and close at exactly the same moment.

- **Elimination of Filling Differences**: Synchronous opening and closing eliminate the minor differences in the filling start and end points of each cavity caused by the time differences in the action of valve pins. This is crucial for filling balance, especially when there are minor differences in the cavities themselves or when it is difficult to achieve perfect balance in the runner design.

- **Enhanced Product Consistency**: Synchronous filling significantly improves the consistency of multi - cavity products in terms of dimensions, weight, appearance (such as weld line position, flow marks, gloss) and mechanical properties, reducing the rejection rate and post - sorting costs.

### Precise Filling Control

- **Accurate Control of Filling Time Window**: Synchronization ensures that each cavity starts and ends filling at the set precise time points. This is crucial for controlling the shear rate, avoiding material degradation, controlling the position and strength of weld lines, and preventing flash or short shots.

- **Optimized Packing Stage**: Synchronous closing ensures that all cavities enter the packing stage simultaneously, and the packing pressure can be transmitted more evenly to all products, reducing dimensional differences and internal stresses caused by uneven packing.

### Simplified Structure and High Reliability

- **Few Driving Units**: The entire system usually only requires one or a few (for large - scale systems, it may be divided into zones) powerful driving sources (cylinders or hydraulic cylinders) to push the stripper plate, instead of equipping each valve pin with a separate driving device (cylinder/hydraulic cylinder).

- **Reduced Failure Points**: Fewer driving components mean fewer potential failure points (such as solenoid valve failures, cylinder seal failures, air/tube leaks), improving the overall reliability and stability of the system.

- **Simplified Maintenance**: Maintenance points are more concentrated, making it easier to inspect and maintain the driving system.

### Cost - effectiveness (Especially for High - cavity Molds)

- **Reduced Driving Costs**: For molds with a very large number of cavities (such as 64 - cavity, 128 - cavity or more), the cost of individually configuring driving devices (cylinder/hydraulic cylinder + solenoid valve + pipeline) for each valve pin will be very high. The stripper plate structure significantly reduces the number of driving units, significantly reducing the initial hardware costs.

- **Reduced Control Costs**: The control system is also simplified, and the number of control channels (I/O points) required is greatly reduced.

- **Reduced Maintenance Costs**: Fewer components also mean lower long - term maintenance and spare parts costs.

### Improved Production Stability

- **Reduced Variables**: Uncertain factors such as response time differences and pressure fluctuations that may exist among multiple independent driving units are eliminated, making the production process more stable and controllable.

- **Strong Adaptability**: It has relatively low requirements for the supply stability of compressed air or hydraulic oil, because the fluctuations of a single powerful driving source have much less impact on synchronization than the respective fluctuations of multiple small driving sources.

### Suitable for Specific High - demand Products

- **Precision Parts**: Products with extremely high requirements for dimensional tolerances (such as electronic connectors, optical components, medical parts).

- **Thin - walled Products**: Products that require extremely fast and precise filling to avoid premature cooling.

- **Products with High Appearance Requirements**: Products that require strict control of weld line positions, avoidance of flow marks or ensuring surface gloss consistency (such as mirror - finished casings, decorative parts).

- **Shear - sensitive Materials**: Materials that require precise control of filling time and shear rate to prevent material degradation.

- **Multi - cavity Products with High Consistency Requirements**: Any application that requires products produced from multiple cavities to be almost identical.

### Aspects Requiring Attention

- **High Requirements for Machining and Assembly Precision**: The machining and assembly precision of the stripper plate itself and the related guiding mechanisms is extremely high to ensure that all valve pins are evenly stressed and move smoothly without jamming. Otherwise, the advantage of synchronization will be lost and even problems may occur.

- **Mold Space Requirements**: The stripper plate mechanism requires additional mold space (height), which may increase the overall thickness of the mold.

- **Flexibility Limitations**: All valve pins must act simultaneously, and independent timing control of individual cavities (such as sequential valve control) cannot be achieved. It is not applicable in special scenarios where the filling time needs to be deliberately staggered to optimize the filling of specific cavities.

- **Potential Wear Points**: The contact points between the stripper plate and the driving rods and guides are potential wear points, which require good lubrication and maintenance.### Unparalleled Synchronization (Core Advantage)

- **Simultaneous Action of All Valve Pins**: This is the most core advantage of the stripper plate structure. A precise stripper plate (ejector plate) drives the valve pins of all cavities simultaneously, ensuring that all gates open and close at exactly the same moment.

- **Elimination of Filling Differences**: Synchronous opening and closing eliminate the minor differences in the filling start and end points of each cavity caused by the time differences in the action of valve pins. This is crucial for filling balance, especially when there are minor differences in the cavities themselves or when it is difficult to achieve perfect balance in the runner design.

- **Enhanced Product Consistency**: Synchronous filling significantly improves the consistency of multi - cavity products in terms of dimensions, weight, appearance (such as weld line position, flow marks, gloss) and mechanical properties, reducing the rejection rate and post - sorting costs.

### Precise Filling Control

- **Accurate Control of Filling Time Window**: Synchronization ensures that each cavity starts and ends filling at the set precise time points. This is crucial for controlling the shear rate, avoiding material degradation, controlling the position and strength of weld lines, and preventing flash or short shots.

- **Optimized Packing Stage**: Synchronous closing ensures that all cavities enter the packing stage simultaneously, and the packing pressure can be transmitted more evenly to all products, reducing dimensional differences and internal stresses caused by uneven packing.

### Simplified Structure and High Reliability

- **Few Driving Units**: The entire system usually only requires one or a few (for large - scale systems, it may be divided into zones) powerful driving sources (cylinders or hydraulic cylinders) to push the stripper plate, instead of equipping each valve pin with a separate driving device (cylinder/hydraulic cylinder).

- **Reduced Failure Points**: Fewer driving components mean fewer potential failure points (such as solenoid valve failures, cylinder seal failures, air/tube leaks), improving the overall reliability and stability of the system.

- **Simplified Maintenance**: Maintenance points are more concentrated, making it easier to inspect and maintain the driving system.

### Cost - effectiveness (Especially for High - cavity Molds)

- **Reduced Driving Costs**: For molds with a very large number of cavities (such as 64 - cavity, 128 - cavity or more), the cost of individually configuring driving devices (cylinder/hydraulic cylinder + solenoid valve + pipeline) for each valve pin will be very high. The stripper plate structure significantly reduces the number of driving units, significantly reducing the initial hardware costs.

- **Reduced Control Costs**: The control system is also simplified, and the number of control channels (I/O points) required is greatly reduced.

- **Reduced Maintenance Costs**: Fewer components also mean lower long - term maintenance and spare parts costs.

### Improved Production Stability

- **Reduced Variables**: Uncertain factors such as response time differences and pressure fluctuations that may exist among multiple independent driving units are eliminated, making the production process more stable and controllable.

- **Strong Adaptability**: It has relatively low requirements for the supply stability of compressed air or hydraulic oil, because the fluctuations of a single powerful driving source have much less impact on synchronization than the respective fluctuations of multiple small driving sources.

### Suitable for Specific High - demand Products

- **Precision Parts**: Products with extremely high requirements for dimensional tolerances (such as electronic connectors, optical components, medical parts).

- **Thin - walled Products**: Products that require extremely fast and precise filling to avoid premature cooling.

- **Products with High Appearance Requirements**: Products that require strict control of weld line positions, avoidance of flow marks or ensuring surface gloss consistency (such as mirror - finished casings, decorative parts).

- **Shear - sensitive Materials**: Materials that require precise control of filling time and shear rate to prevent material degradation.

- **Multi - cavity Products with High Consistency Requirements**: Any application that requires products produced from multiple cavities to be almost identical.

### Aspects Requiring Attention

- **High Requirements for Machining and Assembly Precision**: The machining and assembly precision of the stripper plate itself and the related guiding mechanisms is extremely high to ensure that all valve pins are evenly stressed and move smoothly without jamming. Otherwise, the advantage of synchronization will be lost and even problems may occur.

- **Mold Space Requirements**: The stripper plate mechanism requires additional mold space (height), which may increase the overall thickness of the mold.

- **Flexibility Limitations**: All valve pins must act simultaneously, and independent timing control of individual cavities (such as sequential valve control) cannot be achieved. It is not applicable in special scenarios where the filling time needs to be deliberately staggered to optimize the filling of specific cavities.

- **Potential Wear Points**: The contact points between the stripper plate and the driving rods and guides are potential wear points, which require good lubrication and maintenance.

-

Simultaneous Action of All Valve Pins: This is the

most core advantage of the stripper plate structure. A precise stripper

plate (ejector plate) drives the valve pins of all cavities

simultaneously, ensuring that all gates open and close at exactly the

same moment.

-

Elimination of Filling Differences: Synchronous

opening and closing eliminate the minor differences in the filling start

and end points of each cavity caused by the time differences in the

action of valve pins. This is crucial for filling balance, especially

when there are minor differences in the cavities themselves or when it

is difficult to achieve perfect balance in the runner design.

-

Enhanced Product Consistency: Synchronous filling

significantly improves the consistency of multi - cavity products in

terms of dimensions, weight, appearance (such as weld line position,

flow marks, gloss) and mechanical properties, reducing the rejection

rate and post - sorting costs.

### Unparalleled Synchronization (Core Advantage)

- **Simultaneous Action of All Valve Pins**: This is the most core advantage of the stripper plate structure. A precise stripper plate (ejector plate) drives the valve pins of all cavities simultaneously, ensuring that all gates open and close at exactly the same moment.

- **Elimination of Filling Differences**: Synchronous opening and closing eliminate the minor differences in the filling start and end points of each cavity caused by the time differences in the action of valve pins. This is crucial for filling balance, especially when there are minor differences in the cavities themselves or when it is difficult to achieve perfect balance in the runner design.

- **Enhanced Product Consistency**: Synchronous filling significantly improves the consistency of multi - cavity products in terms of dimensions, weight, appearance (such as weld line position, flow marks, gloss) and mechanical properties, reducing the rejection rate and post - sorting costs.

### Precise Filling Control

- **Accurate Control of Filling Time Window**: Synchronization ensures that each cavity starts and ends filling at the set precise time points. This is crucial for controlling the shear rate, avoiding material degradation, controlling the position and strength of weld lines, and preventing flash or short shots.

- **Optimized Packing Stage**: Synchronous closing ensures that all cavities enter the packing stage simultaneously, and the packing pressure can be transmitted more evenly to all products, reducing dimensional differences and internal stresses caused by uneven packing.

### Simplified Structure and High Reliability

- **Few Driving Units**: The entire system usually only requires one or a few (for large - scale systems, it may be divided into zones) powerful driving sources (cylinders or hydraulic cylinders) to push the stripper plate, instead of equipping each valve pin with a separate driving device (cylinder/hydraulic cylinder).

- **Reduced Failure Points**: Fewer driving components mean fewer potential failure points (such as solenoid valve failures, cylinder seal failures, air/tube leaks), improving the overall reliability and stability of the system.

- **Simplified Maintenance**: Maintenance points are more concentrated, making it easier to inspect and maintain the driving system.

### Cost - effectiveness (Especially for High - cavity Molds)

- **Reduced Driving Costs**: For molds with a very large number of cavities (such as 64 - cavity, 128 - cavity or more), the cost of individually configuring driving devices (cylinder/hydraulic cylinder + solenoid valve + pipeline) for each valve pin will be very high. The stripper plate structure significantly reduces the number of driving units, significantly reducing the initial hardware costs.

- **Reduced Control Costs**: The control system is also simplified, and the number of control channels (I/O points) required is greatly reduced.

- **Reduced Maintenance Costs**: Fewer components also mean lower long - term maintenance and spare parts costs.

### Improved Production Stability

- **Reduced Variables**: Uncertain factors such as response time differences and pressure fluctuations that may exist among multiple independent driving units are eliminated, making the production process more stable and controllable.

- **Strong Adaptability**: It has relatively low requirements for the supply stability of compressed air or hydraulic oil, because the fluctuations of a single powerful driving source have much less impact on synchronization than the respective fluctuations of multiple small driving sources.

### Suitable for Specific High - demand Products

- **Precision Parts**: Products with extremely high requirements for dimensional tolerances (such as electronic connectors, optical components, medical parts).

- **Thin - walled Products**: Products that require extremely fast and precise filling to avoid premature cooling.

- **Products with High Appearance Requirements**: Products that require strict control of weld line positions, avoidance of flow marks or ensuring surface gloss consistency (such as mirror - finished casings, decorative parts).

- **Shear - sensitive Materials**: Materials that require precise control of filling time and shear rate to prevent material degradation.

- **Multi - cavity Products with High Consistency Requirements**: Any application that requires products produced from multiple cavities to be almost identical.

### Aspects Requiring Attention

- **High Requirements for Machining and Assembly Precision**: The machining and assembly precision of the stripper plate itself and the related guiding mechanisms is extremely high to ensure that all valve pins are evenly stressed and move smoothly without jamming. Otherwise, the advantage of synchronization will be lost and even problems may occur.

- **Mold Space Requirements**: The stripper plate mechanism requires additional mold space (height), which may increase the overall thickness of the mold.

- **Flexibility Limitations**: All valve pins must act simultaneously, and independent timing control of individual cavities (such as sequential valve control) cannot be achieved. It is not applicable in special scenarios where the filling time needs to be deliberately staggered to optimize the filling of specific cavities.

- **Potential Wear Points**: The contact points between the stripper plate and the driving rods and guides are potential wear points, which require good lubrication and maintenance.### Unparalleled Synchronization (Core Advantage)

- **Simultaneous Action of All Valve Pins**: This is the most core advantage of the stripper plate structure. A precise stripper plate (ejector plate) drives the valve pins of all cavities simultaneously, ensuring that all gates open and close at exactly the same moment.

- **Elimination of Filling Differences**: Synchronous opening and closing eliminate the minor differences in the filling start and end points of each cavity caused by the time differences in the action of valve pins. This is crucial for filling balance, especially when there are minor differences in the cavities themselves or when it is difficult to achieve perfect balance in the runner design.

- **Enhanced Product Consistency**: Synchronous filling significantly improves the consistency of multi - cavity products in terms of dimensions, weight, appearance (such as weld line position, flow marks, gloss) and mechanical properties, reducing the rejection rate and post - sorting costs.

### Precise Filling Control

- **Accurate Control of Filling Time Window**: Synchronization ensures that each cavity starts and ends filling at the set precise time points. This is crucial for controlling the shear rate, avoiding material degradation, controlling the position and strength of weld lines, and preventing flash or short shots.

- **Optimized Packing Stage**: Synchronous closing ensures that all cavities enter the packing stage simultaneously, and the packing pressure can be transmitted more evenly to all products, reducing dimensional differences and internal stresses caused by uneven packing.

### Simplified Structure and High Reliability

- **Few Driving Units**: The entire system usually only requires one or a few (for large - scale systems, it may be divided into zones) powerful driving sources (cylinders or hydraulic cylinders) to push the stripper plate, instead of equipping each valve pin with a separate driving device (cylinder/hydraulic cylinder).

- **Reduced Failure Points**: Fewer driving components mean fewer potential failure points (such as solenoid valve failures, cylinder seal failures, air/tube leaks), improving the overall reliability and stability of the system.

- **Simplified Maintenance**: Maintenance points are more concentrated, making it easier to inspect and maintain the driving system.

### Cost - effectiveness (Especially for High - cavity Molds)

- **Reduced Driving Costs**: For molds with a very large number of cavities (such as 64 - cavity, 128 - cavity or more), the cost of individually configuring driving devices (cylinder/hydraulic cylinder + solenoid valve + pipeline) for each valve pin will be very high. The stripper plate structure significantly reduces the number of driving units, significantly reducing the initial hardware costs.

- **Reduced Control Costs**: The control system is also simplified, and the number of control channels (I/O points) required is greatly reduced.

- **Reduced Maintenance Costs**: Fewer components also mean lower long - term maintenance and spare parts costs.

### Improved Production Stability

- **Reduced Variables**: Uncertain factors such as response time differences and pressure fluctuations that may exist among multiple independent driving units are eliminated, making the production process more stable and controllable.

- **Strong Adaptability**: It has relatively low requirements for the supply stability of compressed air or hydraulic oil, because the fluctuations of a single powerful driving source have much less impact on synchronization than the respective fluctuations of multiple small driving sources.

### Suitable for Specific High - demand Products

- **Precision Parts**: Products with extremely high requirements for dimensional tolerances (such as electronic connectors, optical components, medical parts).

- **Thin - walled Products**: Products that require extremely fast and precise filling to avoid premature cooling.

- **Products with High Appearance Requirements**: Products that require strict control of weld line positions, avoidance of flow marks or ensuring surface gloss consistency (such as mirror - finished casings, decorative parts).

- **Shear - sensitive Materials**: Materials that require precise control of filling time and shear rate to prevent material degradation.

- **Multi - cavity Products with High Consistency Requirements**: Any application that requires products produced from multiple cavities to be almost identical.

### Aspects Requiring Attention

- **High Requirements for Machining and Assembly Precision**: The machining and assembly precision of the stripper plate itself and the related guiding mechanisms is extremely high to ensure that all valve pins are evenly stressed and move smoothly without jamming. Otherwise, the advantage of synchronization will be lost and even problems may occur.

- **Mold Space Requirements**: The stripper plate mechanism requires additional mold space (height), which may increase the overall thickness of the mold.

- **Flexibility Limitations**: All valve pins must act simultaneously, and independent timing control of individual cavities (such as sequential valve control) cannot be achieved. It is not applicable in special scenarios where the filling time needs to be deliberately staggered to optimize the filling of specific cavities.

- **Potential Wear Points**: The contact points between the stripper plate and the driving rods and guides are potential wear points, which require good lubrication and maintenance.### Unparalleled Synchronization (Core Advantage)

- **Simultaneous Action of All Valve Pins**: This is the most core advantage of the stripper plate structure. A precise stripper plate (ejector plate) drives the valve pins of all cavities simultaneously, ensuring that all gates open and close at exactly the same moment.

- **Elimination of Filling Differences**: Synchronous opening and closing eliminate the minor differences in the filling start and end points of each cavity caused by the time differences in the action of valve pins. This is crucial for filling balance, especially when there are minor differences in the cavities themselves or when it is difficult to achieve perfect balance in the runner design.

- **Enhanced Product Consistency**: Synchronous filling significantly improves the consistency of multi - cavity products in terms of dimensions, weight, appearance (such as weld line position, flow marks, gloss) and mechanical properties, reducing the rejection rate and post - sorting costs.

### Precise Filling Control

- **Accurate Control of Filling Time Window**: Synchronization ensures that each cavity starts and ends filling at the set precise time points. This is crucial for controlling the shear rate, avoiding material degradation, controlling the position and strength of weld lines, and preventing flash or short shots.

- **Optimized Packing Stage**: Synchronous closing ensures that all cavities enter the packing stage simultaneously, and the packing pressure can be transmitted more evenly to all products, reducing dimensional differences and internal stresses caused by uneven packing.

### Simplified Structure and High Reliability

- **Few Driving Units**: The entire system usually only requires one or a few (for large - scale systems, it may be divided into zones) powerful driving sources (cylinders or hydraulic cylinders) to push the stripper plate, instead of equipping each valve pin with a separate driving device (cylinder/hydraulic cylinder).

- **Reduced Failure Points**: Fewer driving components mean fewer potential failure points (such as solenoid valve failures, cylinder seal failures, air/tube leaks), improving the overall reliability and stability of the system.

- **Simplified Maintenance**: Maintenance points are more concentrated, making it easier to inspect and maintain the driving system.

### Cost - effectiveness (Especially for High - cavity Molds)

- **Reduced Driving Costs**: For molds with a very large number of cavities (such as 64 - cavity, 128 - cavity or more), the cost of individually configuring driving devices (cylinder/hydraulic cylinder + solenoid valve + pipeline) for each valve pin will be very high. The stripper plate structure significantly reduces the number of driving units, significantly reducing the initial hardware costs.

- **Reduced Control Costs**: The control system is also simplified, and the number of control channels (I/O points) required is greatly reduced.

- **Reduced Maintenance Costs**: Fewer components also mean lower long - term maintenance and spare parts costs.

### Improved Production Stability

- **Reduced Variables**: Uncertain factors such as response time differences and pressure fluctuations that may exist among multiple independent driving units are eliminated, making the production process more stable and controllable.

- **Strong Adaptability**: It has relatively low requirements for the supply stability of compressed air or hydraulic oil, because the fluctuations of a single powerful driving source have much less impact on synchronization than the respective fluctuations of multiple small driving sources.

### Suitable for Specific High - demand Products

- **Precision Parts**: Products with extremely high requirements for dimensional tolerances (such as electronic connectors, optical components, medical parts).

- **Thin - walled Products**: Products that require extremely fast and precise filling to avoid premature cooling.

- **Products with High Appearance Requirements**: Products that require strict control of weld line positions, avoidance of flow marks or ensuring surface gloss consistency (such as mirror - finished casings, decorative parts).

- **Shear - sensitive Materials**: Materials that require precise control of filling time and shear rate to prevent material degradation.

- **Multi - cavity Products with High Consistency Requirements**: Any application that requires products produced from multiple cavities to be almost identical.

### Aspects Requiring Attention

- **High Requirements for Machining and Assembly Precision**: The machining and assembly precision of the stripper plate itself and the related guiding mechanisms is extremely high to ensure that all valve pins are evenly stressed and move smoothly without jamming. Otherwise, the advantage of synchronization will be lost and even problems may occur.

- **Mold Space Requirements**: The stripper plate mechanism requires additional mold space (height), which may increase the overall thickness of the mold.

- **Flexibility Limitations**: All valve pins must act simultaneously, and independent timing control of individual cavities (such as sequential valve control) cannot be achieved. It is not applicable in special scenarios where the filling time needs to be deliberately staggered to optimize the filling of specific cavities.

- **Potential Wear Points**: The contact points between the stripper plate and the driving rods and guides are potential wear points, which require good lubrication and maintenance.

.png)

.png)